Daki-daki

Silike Si-TPV 2150 Series elastomer ne mai ƙarfi mai ƙarfi na silicone, wanda aka haɓaka ta amfani da fasahar dacewa ta ci gaba. Wannan tsari yana tarwatsa robar silicone zuwa SEBS a matsayin ƙananan barbashi, daga 1 zuwa 3 microns a ƙarƙashin na'urar gani. Waɗannan kayan na musamman sun haɗa ƙarfi, ƙarfi, da juriya na abrasion na thermoplastic elastomers tare da kyawawan kaddarorin silicone, kamar taushi, jin daɗin siliki, da juriya ga hasken UV da sinadarai. Bugu da ƙari, kayan Si-TPV ana iya sake yin amfani da su kuma ana iya sake amfani da su a cikin tsarin masana'antu na gargajiya.

Ana iya amfani da Si-TPV kai tsaye azaman albarkatun ƙasa, musamman an tsara shi don aikace-aikacen gyare-gyare masu laushi-taushi a cikin kayan lantarki masu sawa, lokuta masu kariya don na'urorin lantarki, kayan haɗin mota, manyan TPEs masu tsayi, da masana'antar waya ta TPE.

Bayan amfani da shi kai tsaye, Si-TPV kuma na iya zama mai gyara polymer da ƙari na tsari don elastomers na thermoplastic ko wasu polymers. Yana haɓaka elasticity, inganta aiki, da haɓaka kaddarorin ƙasa. Lokacin da aka haɗe tare da TPE ko TPU, Si-TPV yana ba da santsi mai dorewa mai dorewa da jin daɗin taɓawa, yayin da yake haɓaka karce da juriya. Yana rage taurin ba tare da cutar da kayan inji ba kuma yana ba da mafi kyawun tsufa, rawaya, da juriya. Hakanan zai iya haifar da ƙarancin matte mai kyawawa a saman.

Ba kamar silicone additives na al'ada ba, ana ba da Si-TPV a cikin nau'in pellet kuma ana sarrafa shi kamar thermoplastic. Yana tarwatsewa da kyau da kama-da-wane a cikin matrix polymer, tare da copolymer ya zama mai ɗaure ta jiki zuwa matrix. Wannan yana kawar da damuwa na ƙaura ko al'amurran da suka shafi "blooming", yana sa Si-TPV ya zama mafita mai inganci da sabbin abubuwa don cimma saman siliki mai laushi a cikin elastomers na thermoplastic ko wasu polymers. kuma baya buƙatar ƙarin sarrafawa ko matakan rufewa.

Mabuɗin Amfani

- A cikin TPE

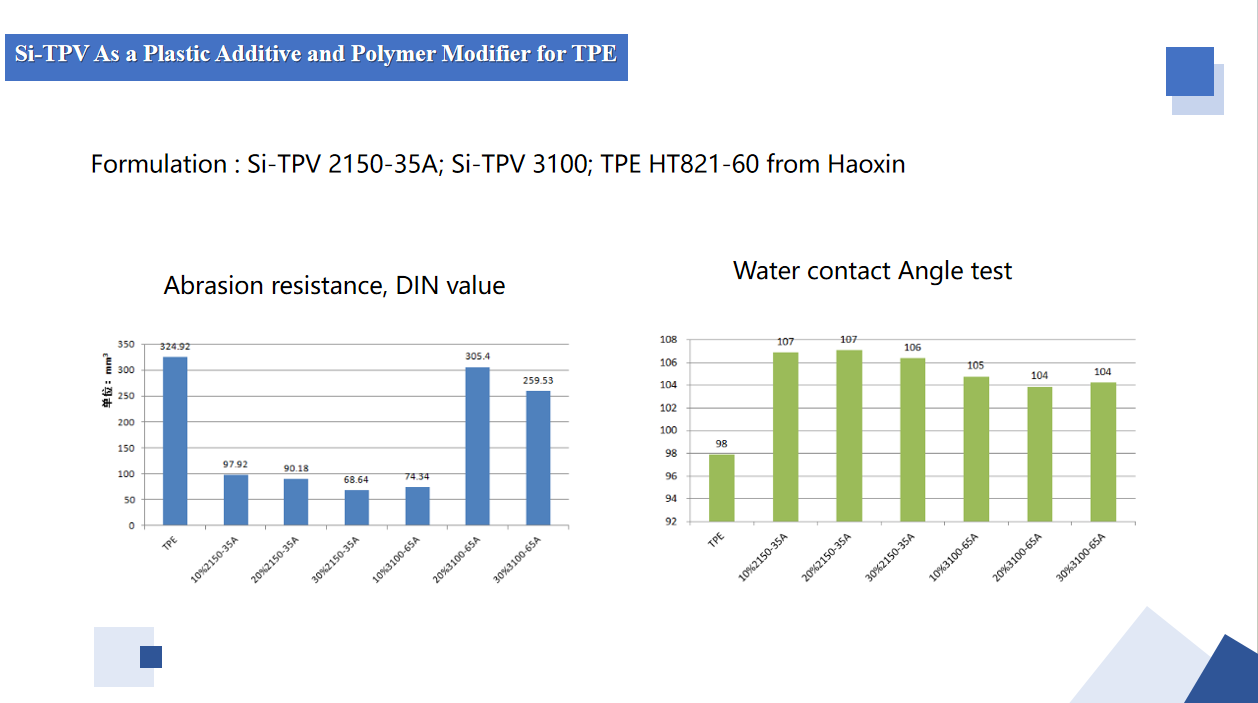

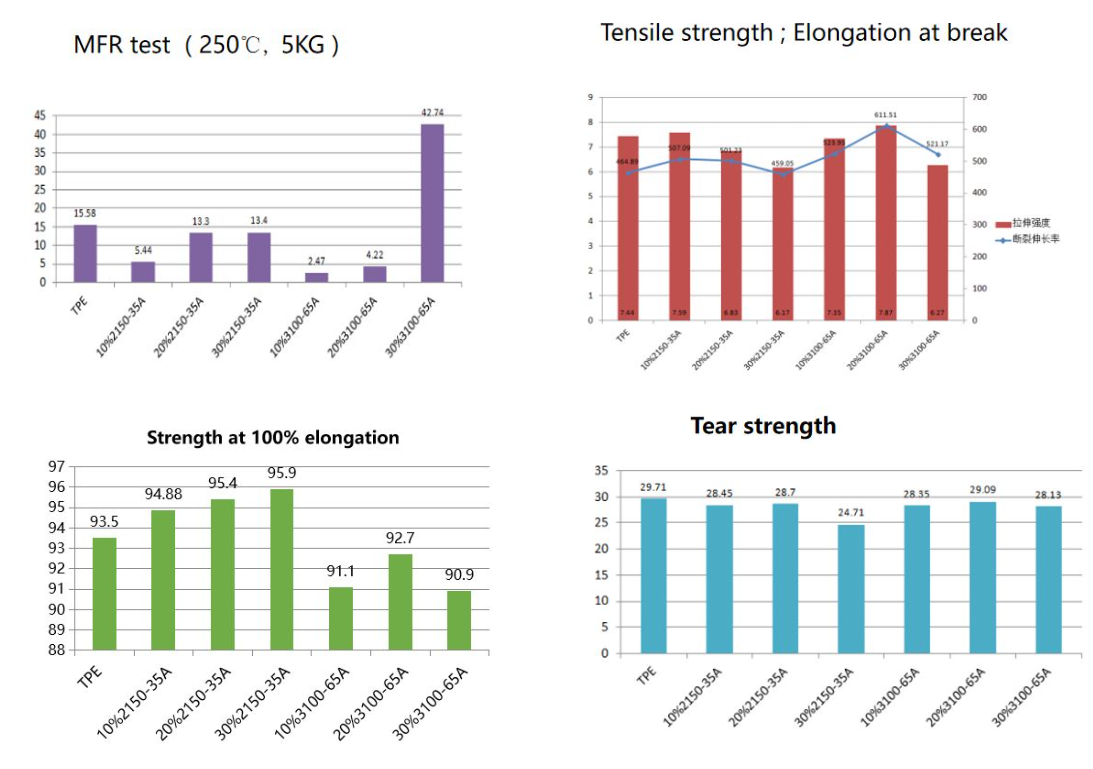

- 1. juriya abrasion

- 2. Juriya tabo tare da ƙaramin kusurwar lamba na ruwa

- 3. Rage taurin

- 4. Kusan babu tasiri akan kaddarorin inji tare da jerin Si-TPV 2150

- 5. Kyakkyawan haptics, busassun siliki tabawa, babu fure bayan amfani na dogon lokaci

Dorewar Dorewa

- Fasaha mara ƙarfi ta ci gaba, ba tare da robobi ba, babu mai mai laushi, kuma mara wari.

- Kariyar muhalli da sake yin amfani da su.

- Akwai a cikin ƙa'idodi masu dacewa.

Si-TPV filastik ƙari da polymer modifier Case Studies

Si-TPV 2150 jerin yana da halaye na dogon lokacin da fata-friendly taushi touch, mai kyau tabo juriya, babu plasticizer da softener kara, kuma babu hazo bayan dogon lokaci amfani, cewa hidima a matsayin filastik ƙari da polymer modifier, musamman dace amfani da silky m ji thermoplastic elastomers shiri.

Kwatanta Tasirin Si-TPV Plastic Additive da Polymer Modifier akan Ayyukan TPE

Aikace-aikace

Si-TPV yana aiki azaman sabon mai gyara jin jin daɗi da ƙari na sarrafawa don thermoplastic elastomers da sauran polymers. Ana iya haɗa shi da nau'ikan elastomers da injiniyanci ko robobi na gabaɗaya, kamar TPE, TPU, SEBS, PP, PE, COPE, EVA, ABS, da PVC. Waɗannan mafita suna taimakawa haɓaka aikin sarrafawa da haɓaka aikin juriya da ƙaƙƙarfan abubuwan da aka gama.

Babban fa'idar samfuran da aka yi tare da haɗin TPE da Si-TPV shine ƙirƙirar yanayi mai laushi-laushi mara jin daɗi - daidai gwargwado na ƙarshen masu amfani suna tsammanin daga abubuwan da suke taɓawa akai-akai ko sawa. Wannan fasalin na musamman yana faɗaɗa kewayon yuwuwar aikace-aikace don kayan elastomer na TPE a cikin masana'antu da yawa. Bugu da ƙari kuma, haɗawa da Si-TPV a matsayin mai gyarawa yana haɓaka sassauƙa, ƙaƙƙarfan ƙarfi, da dorewa na kayan elastomer, yayin da ke sa tsarin masana'anta ya fi tsada.

Magani:

Kokawa don Haɓaka Ayyukan TPE? Si-TPV Plastic Additives da polymer modifiers Samar da Amsar

Gabatarwa zuwa TPEs

Thermoplastic elastomers (TPEs) an rarraba su ta hanyar sinadaran sinadaran, ciki har da Thermoplastic Olefins (TPE-O), Styrenic Compounds (TPE-S), Thermoplastic Vulcanizates (TPE-V), Polyurethanes (TPE-U), Copolyesters (COPE), da Copolyamides (COPA). Duk da yake polyurethanes da copolyesters na iya zama over-ingineered ga wasu amfani, mafi tsada-tasiri zažužžukan kamar TPE-S da TPE-V sau da yawa bayar da mafi dace da aikace-aikace.

TPEs na al'ada sune haɗin jiki na roba da thermoplastics, amma TPE-Vs sun bambanta ta hanyar samun barbashi na roba waɗanda ke da alaƙa ko gabaɗaya, suna haɓaka aikin su. TPE-Vs sun ƙunshi ƙananan saiti na matsawa, mafi kyawun sinadarai da juriya, da kwanciyar hankali mafi girma, yana sa su dace don maye gurbin roba a hatimi. Sabanin haka, TPEs na al'ada suna ba da sassaucin ƙirar ƙira, ƙarfin ƙarfi mai ƙarfi, elasticity, da launi, yana sa su dace da samfuran kamar kayan masarufi, kayan lantarki, da na'urorin likitanci. Har ila yau, suna da alaƙa da kyau ga madaidaitan kayan aiki kamar PC, ABS, HIPS, da Nylon, wanda ke da fa'ida don aikace-aikacen taɓawa mai taushi.

Kalubale tare da TPEs

TPEs sun haɗu da elasticity tare da ƙarfin injiniya da ƙarfin aiki, yana sa su zama masu dacewa sosai. Abubuwan da suka dace na roba, irin su saitin matsawa da haɓakawa, sun fito ne daga lokacin elastomer, yayin da ƙarfi da tsagewar ya dogara da ɓangaren filastik.

Ana iya sarrafa TPEs kamar thermoplastics na al'ada a yanayin zafi mai tsayi, inda suke shiga lokacin narke, ba da izinin masana'anta mai inganci ta amfani da daidaitattun kayan sarrafa filastik. Yanayin zafin su na aiki kuma sananne ne, wanda ya tashi daga ƙananan yanayin zafi-kusa da wurin canjin gilashin lokaci na elastomer-zuwa yanayin zafi mai girma kusa da wurin narkewa na lokacin thermoplastic- yana ƙara ƙarfinsu.

Koyaya, duk da waɗannan fa'idodin, ƙalubale da yawa sun ci gaba da haɓaka aikin TPEs. Wani babban batu shine wahala wajen daidaita elasticity tare da ƙarfin injina. Haɓaka kadara ɗaya sau da yawa yana zuwa akan farashin ɗayan, yana mai da shi ƙalubale ga masana'antun don haɓaka ƙirar TPE waɗanda ke kiyaye daidaitattun abubuwan da ake so. Bugu da ƙari, TPEs suna da saukin kamuwa da lalacewa ta sama kamar su ɓarna da ɓarna, wanda zai iya yin mummunan tasiri ga bayyanar da ayyukan samfuran da aka yi daga waɗannan kayan.