Cikakkun bayanai

SILIKE Si-TPV 2150 Series wani elastomer ne mai ƙarfi wanda aka yi da silicone mai ƙarfi, wanda aka haɓaka ta amfani da fasahar daidaitawa ta zamani. Wannan tsari yana watsa robar silicone zuwa SEBS a matsayin ƙananan barbashi, waɗanda suka kama daga microns 1 zuwa 3 a ƙarƙashin na'urar hangen nesa. Waɗannan kayan na musamman sun haɗa ƙarfi, tauri, da juriyar gogewa na elastomers masu zafi tare da kaddarorin silicone da ake so, kamar laushi, jin siliki, da juriya ga hasken UV da sinadarai. Bugu da ƙari, ana iya sake amfani da kayan Si-TPV kuma ana iya sake amfani da su a cikin hanyoyin masana'antu na gargajiya.

Ana iya amfani da Si-TPV kai tsaye a matsayin kayan aiki, musamman don aikace-aikacen ƙera kayan lantarki masu laushi a cikin na'urorin lantarki masu sawa, akwatunan kariya ga na'urorin lantarki, kayan aikin mota, manyan TPEs, da masana'antar waya ta TPE.

Bayan amfani da shi kai tsaye, Si-TPV kuma zai iya zama mai gyara polymer da ƙari na sarrafawa ga elastomers na thermoplastic ko wasu polymers. Yana haɓaka sassauci, yana inganta sarrafawa, kuma yana haɓaka halayen saman. Idan aka haɗa shi da TPE ko TPU, Si-TPV yana ba da santsi na saman da daɗewa da kuma jin daɗin taɓawa, yayin da kuma yana inganta juriyar karce da gogewa. Yana rage tauri ba tare da yin mummunan tasiri ga halayen injiniya ba kuma yana ba da mafi kyawun tsufa, rawaya, da juriyar tabo. Hakanan yana iya ƙirƙirar ƙarewa mai matte da ake so a saman.

Ba kamar sauran abubuwan da aka ƙara a silicone na gargajiya ba, ana samar da Si-TPV a cikin nau'in pellet kuma ana sarrafa shi kamar thermoplastic. Yana warwatse sosai kuma daidai gwargwado a cikin matrix na polymer, tare da copolymer ɗin da ke ɗaure da matrix. Wannan yana kawar da damuwar ƙaura ko matsalolin "fure", yana mai da Si-TPV mafita mai inganci da ƙirƙira don cimma saman laushi masu laushi a cikin elastomers na thermoplastic ko wasu polymers. kuma baya buƙatar ƙarin matakan sarrafawa ko rufewa.

Muhimman Fa'idodi

- A cikin TPE

- 1. Juriyar ƙazanta

- 2. Juriyar tabo tare da ƙaramin kusurwar hulɗa da ruwa

- 3. Rage tauri

- 4. Kusan babu wani tasiri ga kayan aikin injiniya tare da jerin Si-TPV 2150 ɗinmu

- 5. Kyakkyawan haptics, busasshen siliki, babu fure bayan amfani na dogon lokaci.

Dorewa Dorewa

- Fasaha mai ci gaba wacce ba ta da sinadarai masu narkewa, ba tare da plasticizer ba, babu mai laushi, kuma ba ta da wari.

- Kare muhalli da sake amfani da shi.

- Akwai shi a cikin tsare-tsare masu bin ƙa'idodi.

Nazarin Shari'a na Si-TPV, Ƙarin filastik da Mai Gyara polymer

Jerin Si-TPV 2150 yana da halaye na taɓawa mai laushi mai laushi ga fata na dogon lokaci, juriya ga tabo mai kyau, babu ƙarin mai tacewa da mai laushi, kuma babu ruwan sama bayan amfani na dogon lokaci, wanda ke aiki azaman ƙarin filastik da mai gyara polymer, musamman ana amfani da shi don shirya elastomers masu laushi mai laushi.

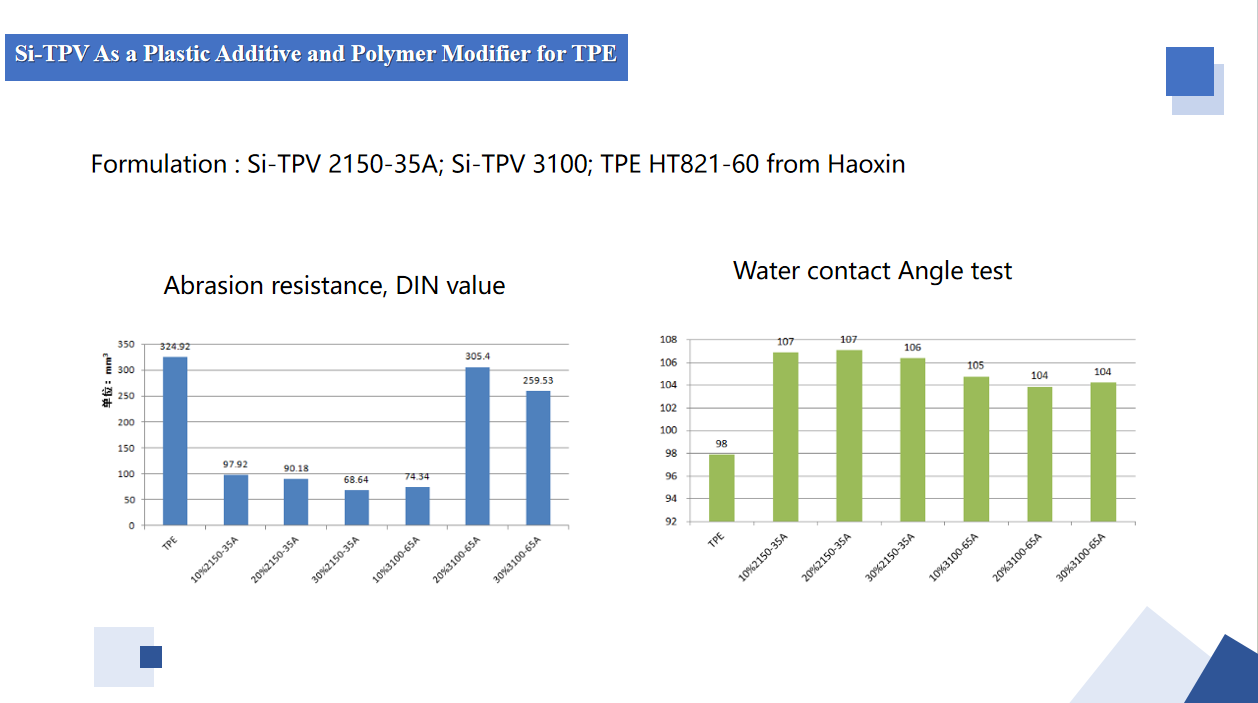

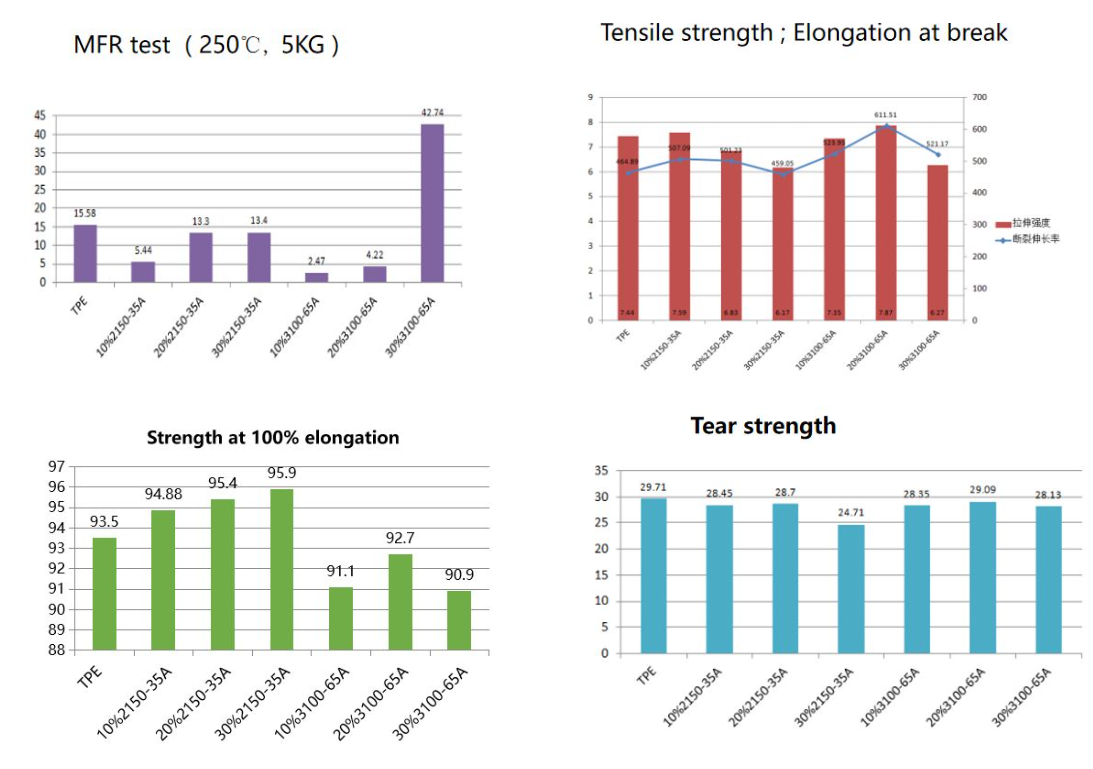

Kwatanta Tasirin Si-TPV Plastic Exdifier da Polymer Modifier akan Aikin TPE

Aikace-aikace

Si-TPV yana aiki a matsayin wani sabon abu mai gyara ji da kuma ƙarin aiki ga elastomers na thermoplastic da sauran polymers. Ana iya haɗa shi da elastomers daban-daban da injiniyanci ko robobi na gabaɗaya, kamar TPE, TPU, SEBS, PP, PE, COPE, EVA, ABS, da PVC. Waɗannan mafita suna taimakawa wajen haɓaka ingancin sarrafawa da inganta aikin karce da juriya na gogewa na kayan da aka gama.

Babban fa'idar samfuran da aka yi da gaurayen TPE da Si-TPV shine ƙirƙirar yanayin laushi mai laushi wanda ba ya taɓawa - daidai ƙwarewar da masu amfani da ƙarshen ke tsammani daga abubuwan da suke taɓawa ko sawa akai-akai. Wannan fasalin na musamman yana faɗaɗa kewayon aikace-aikacen da ake iya amfani da su don kayan elastomer na TPE a cikin masana'antu da yawa. Bugu da ƙari, haɗa Si-TPV a matsayin mai gyara yana haɓaka sassauci, sassauƙa, da dorewar kayan elastomer, yayin da yake sa tsarin kera ya fi araha.

Mafita:

Kuna fama da Ƙoƙarin Ƙara Aikin TPE? Ƙarin Si-TPV na filastik da masu gyaran polymer sun ba da amsar

Gabatarwa ga TPEs

An rarraba na'urorin thermoplastic elastomers (TPEs) ta hanyar sinadaran da suka haɗa da Thermoplastic Olefins (TPE-O), Styrenic Compounds (TPE-S), Thermoplastic Vulcanizates (TPE-V), Polyurethanes (TPE-U), Copolyesters (COPE), da Copolyamides (COPA). Duk da cewa polyurethanes da copolyesters na iya zama waɗanda aka yi musu ƙera fiye da kima don wasu amfani, zaɓuɓɓuka masu rahusa kamar TPE-S da TPE-V galibi suna ba da mafi dacewa ga aikace-aikace.

TPEs na gargajiya cakuda ne na roba da thermoplastics, amma TPE-Vs sun bambanta ta hanyar samun barbashi na roba waɗanda ke da alaƙa da juna ko kuma gaba ɗaya, suna inganta aikinsu. TPE-Vs suna da ƙananan saitin matsi, mafi kyawun juriya ga sinadarai da gogewa, da kuma kwanciyar hankali mafi girma a zafin jiki, wanda hakan ya sa suka dace da maye gurbin roba a cikin hatimi. Sabanin haka, TPEs na gargajiya suna ba da sassauci mafi girma na tsari, ƙarfin juriya mafi girma, sassauci, da launi, wanda hakan ya sa suka dace da kayayyaki kamar kayan masarufi, kayan lantarki, da na'urorin likitanci. Hakanan suna haɗuwa da abubuwa masu tauri kamar PC, ABS, HIPS, da Nylon, wanda ke da amfani ga aikace-aikacen taɓawa mai laushi.

Kalubale tare da TPEs

TPEs suna haɗa sassauci da ƙarfin injina da kuma iya sarrafawa, wanda hakan ke sa su zama masu amfani sosai. Sifofin robarsu, kamar saitin matsewa da tsawaitawa, sun fito ne daga matakin elastomer, yayin da ƙarfin tensile da tsagewa suka dogara ne akan ɓangaren filastik.

Ana iya sarrafa TPEs kamar thermoplastics na gargajiya a yanayin zafi mai yawa, inda suke shiga yanayin narkewa, wanda ke ba da damar yin ƙera kayayyaki masu inganci ta amfani da kayan aikin sarrafa filastik na yau da kullun. Yanayin zafin aikinsu kuma abin lura ne, daga yanayin zafi mai ƙarancin gaske - kusa da wurin canzawar gilashi na matakin elastomer - zuwa yanayin zafi mai yawa wanda ke kusa da wurin narkewa na matakin thermoplastic - yana ƙara musu damar yin amfani da su.

Duk da haka, duk da waɗannan fa'idodi, akwai ƙalubale da dama da ake fuskanta wajen inganta aikin TPEs. Babbar matsala ɗaya ita ce wahalar daidaita sassauci da ƙarfin injina. Inganta wani abu sau da yawa yana zuwa ne da kuɗin ɗayan, wanda hakan ke sa ya zama ƙalubale ga masana'antun su ƙirƙiri tsarin TPE wanda ke kiyaye daidaiton abubuwan da ake so. Bugu da ƙari, TPEs suna iya fuskantar lalacewar saman kamar ƙaiƙayi da mannewa, wanda zai iya yin mummunan tasiri ga bayyanar da aikin samfuran da aka yi da waɗannan kayan.